Blower Drive Service: Ensuring Optimal Performance and Efficiency

A crucial component that often goes unnoticed when it comes to the efficient functioning of machinery and engines is the blower drive. The blower drive system plays a pivotal role in ensuring optimal performance and efficiency in various industries. This article will delve into the significance of blower drive service, its various components, maintenance practices, and benefits.

Understanding Blower Drive System

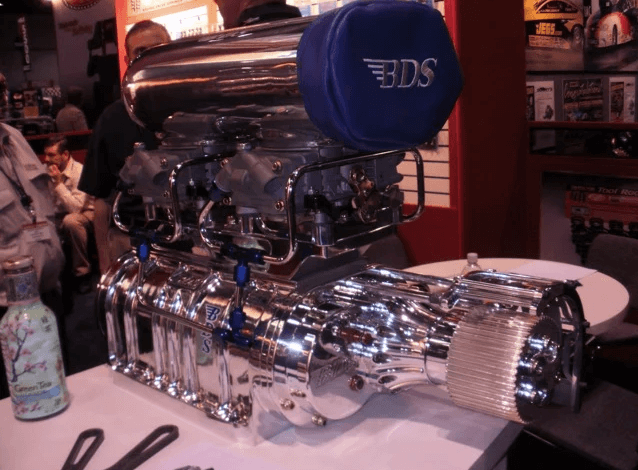

What is a Blower Drive?

A blower drive system is a mechanical setup designed to power and control the operation of blowers. Blowesr are devices used to circulate air or other gases, and they find applications in a wide range of industries, from automotive to industrial manufacturing.

Components of a Blower Drive System

A blower drive system consists of several key components:

1. Blower

The blower itself is the heart of the system, responsible for generating airflow. Choosing the right type and size of blower is essential based on the application’s requirements.

2. Belt-Drive Assembly

The belt-drive assembly connects the blower to the engine’s crankshaft, transferring power from the engine to the blower. Proper alignment and tension are crucial for efficient power transfer.

3. Pulleys and Belts

Pulleys and belts are essential components that enable power transfer between the engine and the blower. They must be in good condition to prevent power loss and ensure smooth operation.

4. Tensioners and Idlers

Tensioners and idlers play a role in maintaining proper belt tension and alignment. These components require regular inspection and adjustment.

Importance of Blower Drive Service

Ensuring Performance and Efficiency

A well-maintained blower drive system directly impacts the equipment’s performance and efficiency. Regular service prevents power loss, overheating, and other issues that can lead to decreased efficiency.

Extending Equipment Lifespan

By addressing wear and tear through regular servicing, the blower’s overall lifespan and the equipment it operates can be significantly extended. This translates to cost savings and reduced downtime.

Maintenance Practices for Blower Drive Systems

Regular Inspections

Frequent visual inspections can help identify signs of wear, misalignment, or belt damage. Catching these issues early prevents more extensive damage down the line.

Lubrication

Proper lubrication of moving parts reduces friction and extends the lifespan of the blower drive system. Lubricants should be selected based on manufacturer recommendations.

Belt Tension Checks

Maintaining the right tension in belts ensures optimal power transfer. Too much tension can lead to premature wear, while too little tension can result in slippage.

Alignment Adjustment

Misaligned pulleys can lead to uneven wear and inefficient power transfer. Regular alignment checks and adjustments are essential.

Benefits of Professional Blower Drive Service

Expertise

Professional blower drive service providers have the experience and knowledge to identify and address issues effectively.

Enhanced Performance

Well-maintained blower drive systems deliver consistent and efficient performance, minimizing unexpected breakdowns.

Cost Savings

Investing in regular maintenance and servicing is a cost-effective strategy in the long run, as it prevents major repairs and extends the lifespan of the equipment. Read more…

Conclusion

In conclusion, a blower drive system plays in various industries. Regular maintenance and professional servicing are essential to ensure the longevity of the system and the equipment it powers. By prioritizing blower drive service, businesses can reap the benefits of enhanced performance, extended lifespan, and overall cost savings.

FAQs

1. How often should blower drive systems be serviced?

Blower drive systems should be serviced at least once a year, but the frequency may vary based on usage and environmental conditions.

2. Can I perform blower drive system maintenance myself?

While basic inspections can be done, relying on professional technicians for comprehensive maintenance is recommended to ensure accuracy.

3. What are signs of a misaligned blower drive system?

Unusual noises, belt squealing, and reduced blower efficiency can indicate a misaligned blower drive system.

4. Are there different types of blowers for specific applications?

Yes, blowers come in various types and sizes, each suited for different applications, such as industrial processes or automotive systems.

5. How can I find a reliable blower drive service provider?

Research online reviews, ask for recommendations, and verify the provider’s experience and credentials before making a decision.